Enhanced Solutions for Water Treatment

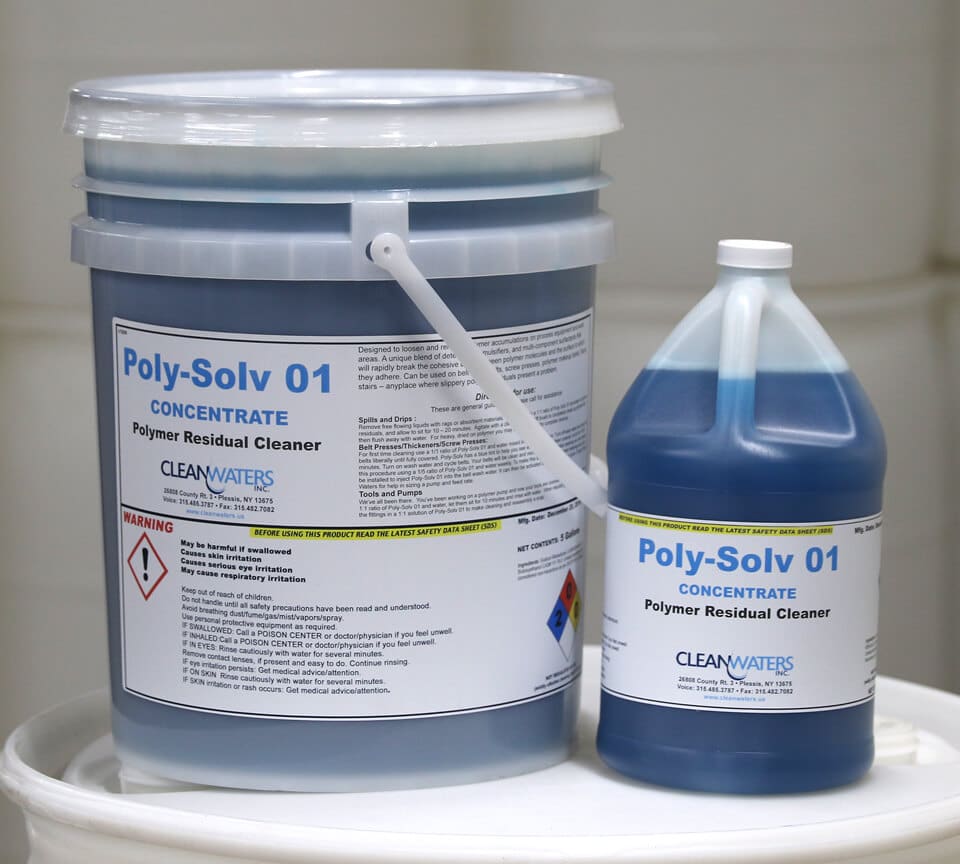

POLY-SOLV 01™

Polymer Residual Cleaner

Designed to loosen and remove polymer accumulations on process equipment and work areas. A unique blend of detergents, emulsifiers, and multi-component surfactants will rapidly break the cohesive bond between polymer molecules and the surface to which they adhere. It can be used on belt press belts, screw presses, polymer makeup tanks, floors, and stairs – anyplace where slippery polymer residuals present a problem.

Benefits of using Poly-Solv 01™ in your polymer areas:

Frequently Asked questions

No, it’s not. Poly-Solv 01™ contains no acids or ammonia. It has been extensively tested and formulated not to harm plastics, metals, or masonry. As with all cleaning products, you should test a small area to make sure that no damage occurs. See SDS for recommended personal protection equipment.

Use a small metering pump to inject Poly-Solv 01™ into the belt press wash water. Activate when performing washdown to keep your belts in clean, optimum condition. We’ve seen many instances when belts were changed when all they really needed was a good cleaning. Contact us for help in sizing and setting up a metering pump. Regular use of Poly-Solv 01™ will extend the life of your belts and save you money.

Depending on the layout of your particular press, for the first cleaning, spray screw areas liberally with a 1/1 ratio of Poly-Solv 01™ and water. Let it sit for 10 – 20 minutes, and initiate the washdown cycle. After initial cleaning, a 1/5 ratio may be used. As with belt presses, injection into the wash water is the easiest method of application.

Yes, you can. Over time polymer residuals will build up in the centrifuge bowl. Periodic cleaning will remove these deposits and increase performance. The easiest method is to feed straight Poly-Solv 01™ through your polymer blending unit’s calibration column, through the blending unit, and into the centrifuge. In a dirty centrifuge you will see polymer residuals and sludge deposits come off in the centrate water. Run until centrate is clean.

Yes, you can, although we have another product, Poly-Solv 02™, designed specifically for this application which is more effective. If using Poly-Solv 01™ do not dilute. Pour into calibration column and feed into metering pump. After product has been fed, use mineral oil to flush cleaner out of the system as residual will affect polymer. Use our Poly-Solv 02™ for an easier more effective way to flush your blending unit.

You can purchase it in 1-gallon jugs (case of 4), 5-gallon pails, 55-gallon drums, and 275-gallon totes.

Directions for use

These are general guidelines. Please call for assistance.

Spills and Drips:

Remove free-flowing liquid with rags or absorbent material. Apply liberally to polymer residuals and allow to sit for 10 – 20 minutes. Agitate with a cleaning rag or stiff brush to completely break up the film, then flush it away with water. For heavy, dried-on residuals, you may need to repeat the process for complete cleanup.

Belt Presses/Thickeners/Screw Presses:

For first-time cleaning, use a 1/1 ratio of Poly-Solv 01™ and water mixed in a spray applicator. Turn off the wash water and spray the belts liberally until fully covered. Poly-Solv™ has a blue tint to help you see which areas have been covered. Let sit for 10-20 minutes. Turn on the wash water and cycle belts. Your belts will be clean and more efficient. After initial cleaning, you may repeat this procedure using a 1/5 ratio of Poly-Solv 01™ and water weekly. To make this task super easy, a small metering pump can be installed to inject Poly-Solv 01™ into the belt wash water. It can then be activated during the washdown cycle. Contact California Environmental Dewatering for help in sizing a pump and feed rate.

Tools and Pumps:

We’ve all been there. You’ve been working on a polymer pump, and now your tools are covered. Just spray them down with straight Poly-Solv 01™, let them sit for a bit, and wash them off. When rebuilding a polymer pump, soak the fittings in Poly-Solv 01™ to make cleaning and reassembly a snap.

POLY-SOLV 02™

Polymer Blending Unit System Flush

Specifically designed for flushing liquid or emulsion polymer blending units. A unique blend of mineral oils, detergents, and surfactants that will keep your blending unit performing at peak capacity. Over time, the polymer will leave deposits in the internal components of the blending units. These deposits will inhibit pumping and mixing, reducing the effectiveness of the polymer and costing you more money.

Benefits of incorporating Poly-Solv 02™ into your blending unit preventive maintenance program:

Poly-Solv 02™ FAQ’s

Most polymer blending units have a calibration column to verify the polymer dose. Pouring Poly-Solv 02™ into the calibration column is the easiest method of introducing it into your system. The non-toxic dye will visually let you know when the unit has been saturated. For systems without a calibration column, you may put a “T” in your polymer feed line with a valve. This will allow you to feed Poly-Solv 02™ directly into the polymer feed pump. Give us a call; we can give you guidance to help you easily modify your system.

This product contains no caustics, no acids, no solvents, and has a neutral pH. It has been tested for compatibility with plastics, glass, and metals. It will not harm your blending unit. It will, however, lubricate and protect wear parts, reducing pump rebuilds.

Yes, you certainly can; however, it is not recommended. Recirculation usually requires modification of the blending unit. Poly-Solv 02™ will clean your unit without the hassle of recirculation. Also, recirculation will require you to use a lot of products; it is not necessary. For best results, run Poly-Solv 02™ through your unit before a shutdown period. The longer it can stay in the system, the better it will work. Overnight is good; over the weekend is great.

Absolutely! Running Poly-Solv 02™ through the unit before storage will ensure an easy startup the next time that you need it. Polymer deposits will dissolve, and pump wear parts will be lubricated. It will also prevent moisture from entering the system.

Yes, you can, although we have another product, Poly-Solv 02™, designed specifically for this application which is more effective. If using Poly-Solv 01™ do not dilute. Pour into calibration column and feed into metering pump. After product has been fed, use mineral oil to flush cleaner out of the system as residual will affect polymer. Use our Poly-Solv 02™ for an easier more effective way to flush your blending unit.

Yes. If you enjoy difficult startups and rebuilding polymer pumps, don’t buy them. But seriously, the cost of 1 pail of Poly-Solv 02™ is much less than most polymer pump rebuild kits. That alone will justify the cost. When you factor in the increased mixing performance of a clean blending unit, this product will save you money. And you also have the confidence of our guarantee. If this product does not work for you, we will issue a 100% refund. Give it a try; you’ll be glad that you did!

Directions for use

Each blending unit is different; these are general guidelines. (Call for assistance.)

First-time application

Fill the blending unit calibration column with Poly-Solv 02™. Shut off the polymer supply and open the calibration column valve. Allow the pump to run long enough to fully saturate the blending unit. Shut off pump and leave overnight. Poly-Solv 02™ will dissolve buildups. For best results, repeat daily for a period, as it will take several applications to initially clean the unit.

Maintenance

After the blending unit has been fully cleaned, Poly-Solv 02™ may be used weekly to maintain the unit. It is best to perform this before a weekend or other extended shutdown. If you process solids daily, a biweekly maintenance program is very beneficial. When rebuilding polymer pumps, soak fittings overnight in Poly-Solv 02™. This will soften deposits and make cleaning much easier. If shutting down a blending unit for an extended period, be sure to run Poly-Solv 02™ in it first. Leave the product in the unit until startup. This will make startups much easier!

Poly-Solv 02™ is not designed for the cleanup of polymer spills; for spills, use our Poly-Solv 01™.

POLY-SOLV 03™

Dry Polymer Absorbant

Finally, an absorbent specifically designed to clean up polymer spills quickly. Our newest product, Poly-Solv 03 Dry™, was created to stop polymer spills from spreading and make cleanup more manageable than ever before.

Clay-type absorbents don’t work well with polymers. You end up using large quantities and still have a mess. They also tend to be dusty. Poly-Solv 03 Dry™ uses a plant-based material that sucks up polymer like a sponge. We added a non-toxic dye that reacts with polymer, so you will know if there is any residual left when you sweep it up. Poly-Solv 03 Dry™ also contains two types of polymer deactivators that help break polymer down on contact. Finally, we incorporated a grit component that helps minimize slipping should you not have time to sweep it up right away.

Consider these advantages of Poly-Solv 03™ Dry over other absorbents:

Give Poly-Solv 03 Dry™ a try today. You will be glad that you did. As with all our Poly-Solv™ products, we offer a 100% money-back guarantee if it doesn’t work to your satisfaction.

Directions for use:

Whenever using any dry absorbants, it is good practice to wear a dust mask. Sprinkle Poly-Solv 03 Dry™ onto a polymer spill as soon as possible so that the entire spill is covered. Polymer exposed to air will develop a film over time that makes cleanup more difficult. Work the Poly-Solv Dry™ into the polymer with a broom/shovel; this helps the deactivators break it down. Let the treated spill sit for 10–20 minutes before sweeping/ shoveling.

If the spill is on a smooth surface, Poly-Solv 03 Dry™ will usually absorb all the polymer. If the spill is on a porous surface, you may see a residual. A blue tint will indicate residual. Any residual should be cleaned with hot water or our Poly-Solv 01™ residual cleaner, which will make it super easy.