CED Vivianite Remover

CED Struvite Remover is the most effective Vivianite Remover on the market. It is a biodegradable non-corrosive organic acid that is the safest and quickest Vivianite Remover on the market. It effectively dissolves Vivianite, Struvite, Calcium Carbonate, and other dense mineral scales. It is safe to use on all equipment including pumps, aerators, heat exchangers, and digesters.

Vivianite Remover Application

Quantity of product being used for Vivianite Removal will be determined by the size of the pipe being treated and the amount of Struvite scale. The types of treatment are Static Soaking or Recirculation (preferred method). Static Soaking takes a minimum of 24 hours and Recirculation takes 2-72 hours. Product application rate for removal is 1.5-2lbs of product per 1lb of Vivianite. No hazmat or OSHA compliance training is required.

Current Methods of Removal

Current treatment methods of removal are hydro-jetting with high pressure streams of water, mechanically grinding pipe walls, replacement of pipelines, and highly corrosive chemicals. The disadvantages of current Vivianite Removal methods are that hydro-jetting, mechanically grinding, and replacement of pipelines are costly, labor intensive, and require a lengthy suspension of normal treatment operations. Many pipelines and valves are underground or are inaccessible for mechanical treatment. Corrosive chemicals cause damage to glass lining of piping and can upset the biologics in the wastewater system.

What is Vivianite?

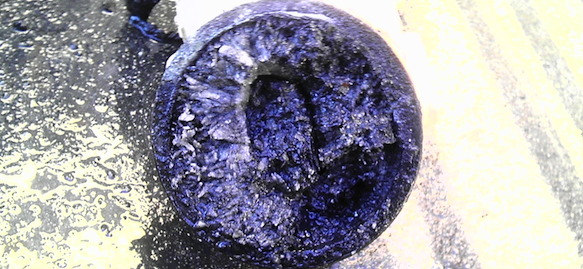

Vivianite, also referred to as ferrous phosphate, formula: Fe++3(PO4)2•8(H2O), is a hydrated iron phosphate mineral that crystallizes as deep blue to bluish green prismatic flattened crystals. It forms in systems where iron salts (Ferrous and Ferric) are added. Iron salts are used in wastewater treatment as a coagulant and settling agent, to help control orthophosphate (PO4 3−) and control hydrogen sulfide (H2S) levels in anaerobic digestion. Control over hydrogen sulfide is essential as it prevents odors and corrosion.

Common Symptoms

Buildup of Vivianite reduces the effectiveness of the pipelines and restricts the flow, leading to more frequent pump failures and reduced plant reliability. Vivianite buildup most often forms in spots with local turbulence, such as pipe elbows, mixer blades and pumps. Common symptoms of Vivianite are:

- Can physically see Vivianite crystallization on plant pipeline

- The flow slows down or is restricted

- An increase in pipeline pressure

- Pipelines vibrating, rattling, or shaking due to restricted flow

- Digester overflow box backing up

Where does Vivianite Form?

Vivianite deposition occurs within:

- Pumps

- Aerators

- Valves

- Heat exchangers

- Digesters

Current Treatment Methods Aren’t Sustainable

Current methods of Vivianite Removal are hydro-jetting with high pressure streams of water, mechanically grinding pipe walls, replacement of pipelines, and highly corrosive chemicals. The disadvantages of these methods are: they require a lengthy suspension of normal treatment operations. Many pipelines and valves are underground or are inaccessible for mechanical removal. Corrosive chemicals cause damage to glass lining of piping and can upset the biologics in the wastewater system.